The suspension of the approval of aluminium phosphide for the non-agricultural control of Norway rats has been lifted. This means that pest professionals holding the correct qualification thats the Level 2 Award in the Safe Use of Aluminium Phosphide for Vertebrate Pest Control – can, once again, use Phostoxin and Talunex for rodent control. However, there is a but and its a big but!

Aluminium phosphide users will recall that label changes relating to the conditions of use of Phostoxin and Talunex for the ‘non-agricultural control of brown rats’ led to a temporary suspension on the use of these products for rodent control. The aim was to come up with a clear and workable process for the UK. Whether or not that has been achieved we leave you to judge.

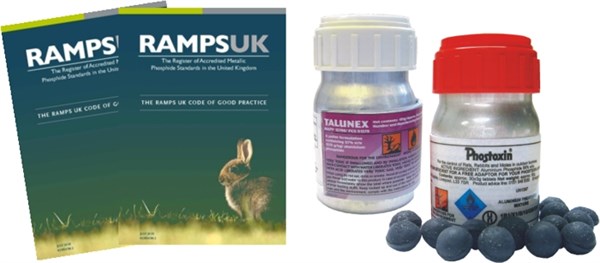

Additional label requirements for the non-agricultural control of brown rats, moles and rabbits covering risk areas and gas level monitoring have been introduced. These are outlined in the updated 2018 version of the RAMPS UK Code of Good Practice. RAMPS is the Register of Accredited Metallic Phosphide Standards. RAMPS says that the new code also gives clear additional guidance on all aspects of agricultural and non-agricultural control of brown rats, moles and rabbits..

|

There are two key changes to the code:

The first seems to be the more problematic. It concerns the identification of the ‘fumigation area’ and the ‘risk area’ and the monitoring requirements post treatment before clearance to enter the area can be granted. The second concerns the cleaning of equipment post use and essentially allows for the washing of equipment provided this is specified on the label and importantly that there is sufficient time to be 100% sure it is completely dry before being re-used. This is necessary to ensure there is no possible contact between any trapped moisture inside the device and the product to be added as this could generate phosphine. Full details are given in appendix 4 of the new code.

The code states that you must: “Identify the fumigation area and the risk area and monitor phosphine gas levels on the perimeter of the risk area and extend it if readings are greater than 0.01ppm. Detailed guidance on how to do this is given in appendix 3 of the document.

The following text is extracted from the code to give you a flavour of the requirements but if you are intending to use aluminium phosphide you will need to read the code carefully. Download the updated RAMPS code.

Selected extracts from the code:

‘The fumigation area is the area in close proximity to directly treated burrows and any runs or other locations from which phosphine gas may possibly escape. It is defined as ‘the area in which treatments are underway and in which product is (or has been) actively applied into burrows. It can be of any shape or of any size depending on the extent of the burrows and its limit is the outer border of where the pest control activity is being conducted.’

The risk area is the area of possible danger around the fumigation area and out to a defined boundary where phosphine gas may be detected.

The risk area must be established at least 25 metres from the edge of the fumigation area but the area can be reduced to a minimum distance of 10 metres if it can be ensured that no person, farm animal or domestic animal will be present within this distance.

The concentration of phosphine outside of this Risk area has to be below 0.01ppm and re-entry of persons into this risk area other than the operator can only be permitted once clearance is granted by the operator and the concentration of phosphine is below 0.01ppm.

Under no circumstances can treatments be conducted if the intended fumigation area is within 10 metres of surface watercourses, ditches human habitation or any non-target burrows, farm or domestic animal habitation.

Monitoring points should be at 10cm and head height and at 5 metre intervals working in from the outer edge of the risk area to the centre of the fumigation area.’

The requirements are certainly clear but how practical are they? Email the editor with your thoughts.